The excavator's main platform (also known as the uppercarriage) is the core operating and control area of the equipment, integrating power, hydraulic, electrical, and driving systems. The reliability and performance of its components directly affect the overall machine's operating efficiency and safety.

Below, starting from the core functional modules, we systematically introduce the key components and technical characteristics of the main platform:

I. Power System Components

Engine Assembly

Main Brands: Cummins, Isuzu, Mitsubishi, etc.

Technical Parameters: Power range 100-600kW, emission standards must meet National IV/Euro V requirements.

Key Features: Equipped with turbocharging, intercoolers, and electronic fuel injection systems to ensure adaptability to high-altitude/cold environments.

Cooling System

Components: Radiator, intercooler, hydraulic oil cooler.

Technical Requirements: Using an aluminum plate-fin structure, the heat dissipation efficiency is increased by 30% or more, adapting to 50℃ high-temperature environments.

II. Hydraulic System Components

Main Pump Assembly

Type: Piston pump (such as Kawasaki K3V, Rexroth A11VO).

Performance Indicators: Displacement 120-300cc/rev, working pressure 35MPa, variable control achieves precise flow regulation.

Main Control Valve

Function: Distributes hydraulic oil to the boom, stick, bucket, and swing mechanism.

Technical Highlights: Load-sensing technology, reducing energy loss by 15%-20%.

Swing Motor and Gearbox

Structure: Planetary gear reducer, transmission ratio 50-80:1.

Performance: Starting torque ≥20000N·m, swing speed 8-12rpm.

III. Electrical and Control System Components

Display and Controller

Function: Integrates engine speed, hydraulic pressure, and fault diagnosis information.

Technology: Supports CAN bus communication, response time ≤50ms.

Sensors

Type: Pressure sensor (range 0-60MPa), angle sensor (accuracy ±0.1°), temperature sensor (-40℃~150℃).

Application: Real-time monitoring of the hydraulic system status to prevent overload.

IV. Cab and Operating Components

Cab Assembly

Safety Standards: Passed ROPS/FOPS certification, impact resistance ≥25kN.

Comfort: Equipped with air suspension seats, automatic air conditioning, and noise reduction materials (noise ≤75dB).

Operating Levers

Type: Electro-hydraulic proportional levers, control accuracy ±1%.

Lifespan: Number of operations ≥5 million times.

V. Structural Parts and Coverings

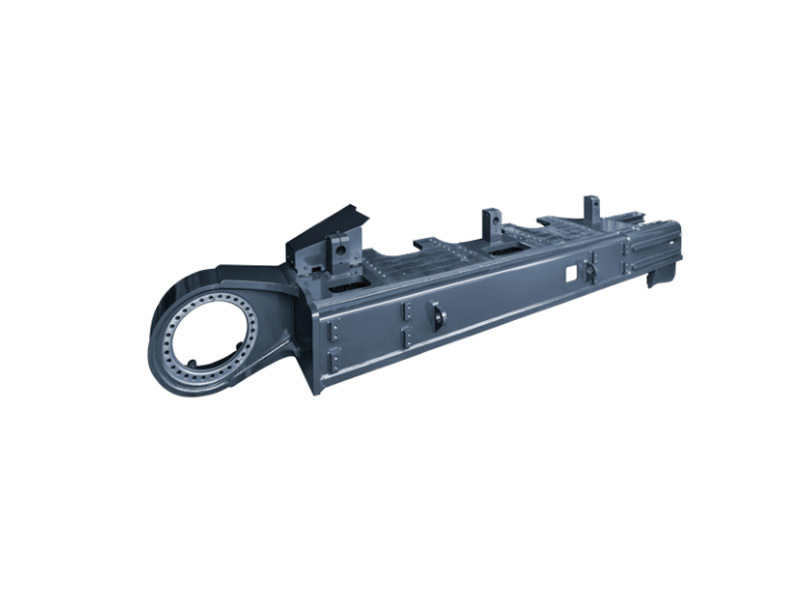

Upper Frame

Material: High-strength steel plate (Q690D), yield strength ≥690MPa.

Process: Overall welding followed by annealing treatment to eliminate internal stress.

Counterweight

Material: Cast iron/concrete composite structure.

Function: Balances the overall machine's center of gravity, improving stability.

VI. Maintenance and Maintenance Components

Filter System

Type: Oil filter, diesel filter, hydraulic oil filter, air filter.

Replacement Cycle: Oil filter 500h, diesel filter 1000h.

Lubrication System

Components: Central lubrication pump, distributor, pipelines.

Function: Automatic timed lubrication, reducing manual maintenance.

VII. Technological Trends and Innovations

Intelligent Upgrades

Remote Monitoring: Real-time upload of equipment status through 5G modules.

Fault Prediction: Based on big data analysis, early warning of hydraulic pump wear.

Energy-Saving Technology

Hybrid Power: Using supercapacitor energy storage, recovering swing braking energy.

Load Matching: Dynamically adjusting engine speed to reduce fuel consumption by 10%-15%.

VIII. Selection Suggestions

Matching According to Working Conditions

Mining Operations: Strengthen structural components, select high-displacement main pumps.

Municipal Engineering: Optimize cab comfort, reduce noise emissions.

Brand and After-Sales Service

Prioritize original equipment parts to ensure compatibility and warranty service.

Spare Parts Inventory: Core components (such as main pumps, main valves) should maintain a 3-6 month usage amount.

The selection of excavator main platform components should comprehensively consider equipment performance, working conditions, and the total life cycle cost. It is recommended to prioritize the use of original or certified parts and conduct regular professional maintenance to ensure efficient and safe operation of the equipment.

Main platform

Keyword:

Category:

Quality Management System

Total Participation:

Upholding the philosophy that quality is life and product is character, Jiuri's management team is fully involved in quality management and improvement, incorporating product quality control into key management content; leaders strengthen communication between departments, clarify work requirements, and each link is interlocked, mutually supervising and promoting each other to jointly ensure product quality.

New Product Quality Management:

Project management; New product quality audit; New product planning; Supplier advance management; APQP development process control.

Manufacturing Process Quality Management:

Quality elite system; Lean production; Total productive maintenance; Statistical process control; PDCA quality management system.

OUR STRENGTH

Service tenet: To provide comprehensive solutions and services to customers from all walks of life

Raw material workshop

Welding robot

Machining Center

RECOMMENDED PRODUCTS

Products cover core structural components such as excavators, loaders, forklifts, and mining machinery, and are exported to international markets.

PRODUCT CONSULTATION

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

Products cover core structural components such as excavators, loaders, forklifts, and mining machinery

Our products cover core structural components such as excavators, loaders, forklifts, and mining machinery

Contact Us

Contact Person:18677228751 Liu An

Email:13977236501@139.com

Address: No. 7, Zhutong Road, Luorong Town, Liuzhou City

QR code

Scan the code to browse the official website