Excavator slewing platform accessories are key components for the excavator's slewing function. The following is a detailed introduction to excavator slewing platform accessory products:

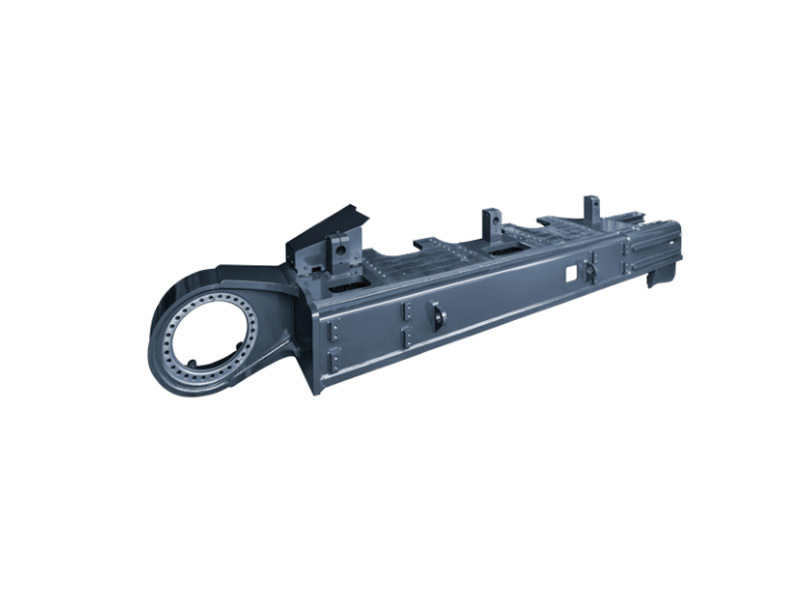

I. Slewing Platform Structure

The slewing platform is the foundation of the entire slewing section of the excavator. Various mechanisms and equipment are installed on it, such as lifting mechanisms, slewing mechanisms, double-foot support bases, electrical cooling devices, air pressure control systems, electrical equipment, and engine sheds, etc. The slewing platform is supported on the annular roller track of the crawler walking part by cylindrical rollers and connected to the walking part by a central pivot.

II. Main Accessory Types

Slewing Bearing Device:

Function: Provides support, supporting the turntable on the fixed part (lower chassis), preventing tipping, and ensuring smooth and easy slewing.

Types: Rolling bearing type slewing bearing and slewing column type slewing bearing. The rolling bearing type slewing bearing is essentially a large-diameter rolling bearing. Commonly used structures include single-row ball type and double-row ball type.

Slewing Drive Device:

Function: Drives the turntable to slew.

Composition: Generally consists of a slewing hydraulic motor, a planetary reducer, and a slewing drive pinion, etc. Through the meshing transmission of the drive pinion and the inner gear ring, the slewing drive device rotates around the inner gear ring while self-rotating, thereby driving the platform to rotate 360°.

Center Slewing Joint:

Function: Used to connect the hydraulic oil circuit between the travel control valve and the travel motor, ensuring the excavator's 360-degree rotation. Generally, there are two high-pressure hoses connecting the slewing joint to the left and right travel control valves, and two high-pressure oil pipes connecting to the left and right travel motors. In addition, the slewing joint also connects the travel speed pilot pipe and the travel motor return oil pipe.

Oil Seal Kit: The oil seal kit of the center slewing joint is a key component, such as the center slewing oil seal kit of Komatsu PC120-6, which mainly includes ROI oil seals, O-rings, etc. The oil seal kit of the center slewing joint may vary depending on the brand and model of the excavator.

Slewing Pinion and Large Gear Ring:

Function: The slewing pinion meshes with the gear ring on the inner seat ring of the slewing bearing. When the slewing mechanism is working, the pinion can rotate around its own axis and revolve around the center line of the turntable, thereby driving the entire slewing platform to rotate.

III. Accessory Characteristics and Requirements

High Strength and Wear Resistance: Slewing platform accessories need to withstand large loads and friction, so they must have high strength and wear resistance to ensure long-term stable operation.

Good Matching Accuracy: The matching accuracy between slewing platform accessories directly affects the slewing performance and stability of the excavator. Therefore, the dimensional accuracy and form and position tolerances need to be strictly controlled during manufacturing.

Reliable Sealing Performance: The hydraulic system and lubrication system in the slewing platform accessories require reliable sealing performance to prevent leakage and contamination.

Rotary platform

Keyword:

Category:

Quality Management System

Total Participation:

Upholding the philosophy that quality is life and product is character, Jiuri's management team is fully involved in quality management and improvement, incorporating product quality control into key management content; leaders strengthen communication between departments, clarify work requirements, and each link is interlocked, mutually supervising and promoting each other to jointly ensure product quality.

New Product Quality Management:

Project management; New product quality audit; New product planning; Supplier advance management; APQP development process control.

Manufacturing Process Quality Management:

Quality elite system; Lean production; Total productive maintenance; Statistical process control; PDCA quality management system.

OUR STRENGTH

Service tenet: To provide comprehensive solutions and services to customers from all walks of life

Raw material workshop

Welding robot

Machining Center

RECOMMENDED PRODUCTS

Products cover core structural components such as excavators, loaders, forklifts, and mining machinery, and are exported to international markets.

PRODUCT CONSULTATION

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

Products cover core structural components such as excavators, loaders, forklifts, and mining machinery

Our products cover core structural components such as excavators, loaders, forklifts, and mining machinery

Contact Us

Contact Person:18677228751 Liu An

Email:13977236501@139.com

Address: No. 7, Zhutong Road, Luorong Town, Liuzhou City

QR code

Scan the code to browse the official website