TECHNOLOGICAL PROCESS

From scratch, integrated consideration

01

Feeding

Use high-precision instruments to ensure material dimensions

02

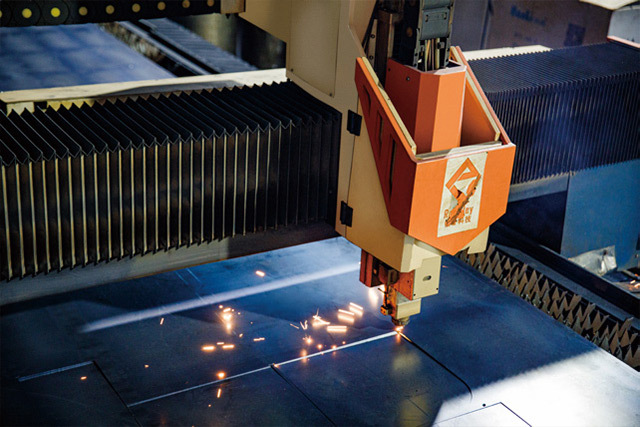

Molding

Equipment is complete and meets different needs

03

Building blocks

Dedicated tooling for each series, ensuring the size of all products

04

Welding

Welding coverage of the robotic arm, special point special treatment

05

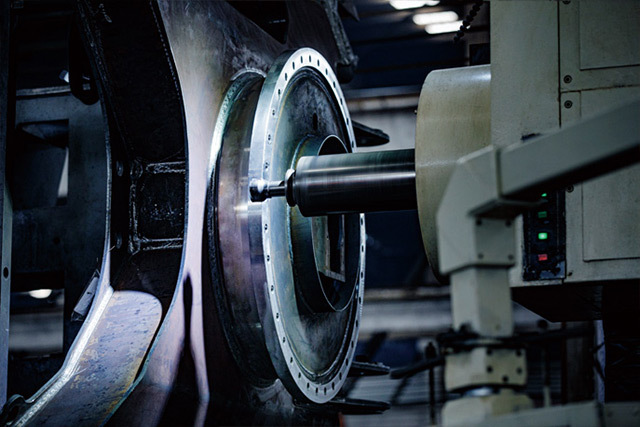

Machining

To haggle over every ounce and every penny; to be unwilling to yield even a fraction.

06

Shot blasting

Good products can withstand the test of time.

07

Paint

Good product, emitting a "bright light"

Products cover core structural components such as excavators, loaders, forklifts, and mining machinery

Our products cover core structural components such as excavators, loaders, forklifts, and mining machinery

Contact Us

Contact Person:18677228751 Liu An

Email:13977236501@139.com

Address: No. 7, Zhutong Road, Luorong Town, Liuzhou City

QR code

Scan the code to browse the official website